For security inspector Charles Ramirez, March 23 obtained off to an excellent start. His staff of specialised contractors from Houston-primarily based JE Benefit had just polished off a celebratory lunch held on the grounds of BP’s large Texas City, Texas, refinery. The 1200-acre facility processes up to 460,000 barrels of raw crude oil a day, and the contractors had just wrapped up their part in its complicated, 9-week “turnaround,” or scheduled maintenance cycle, accident-free. When the lunch hour ended, Ramirez’s colleagues returned to their offices in short-term trailers while he left to run a ultimate safety verify.

What he did not notice as he hustled across the yard was that, just one hundred ft. behind him, the massive steel isomerization unit was being restarted after two weeks spent offline. The “isom” unit, which boosts the octane stage of gasoline, was about to trigger the deadliest U.S. refinery catastrophe in a decade.

Probably the most dangerous time for an oil refinery isn’t when it is operating, however when it is in transition. During a refinery turnaround, some 30,000 separate procedures are performed. Dozens are required to move unstable contents safely out of and into position when the isom unit is coming back on line.

As staff restarted a element of the unit, abnormal stress constructed up within the manufacturing tower, and so three relief valves opened to permit extremely volatile gasoline elements to escape to the 10 x 20-ft. “blowdown” drum. However so much gas flooded into the drum that its capacity was rapidly exceeded. Liquid and vapor shot straight up the 113-ft. vent stack, into the open air.

Witnesses noticed a cloud of vaporizing gas geyser out of the stack and cascade to the ground. One particular person reported hearing a determined call crackle over a handheld radio. “What is this? Stop all hot work! Cease all sizzling work!”

However a lot tools was working to shut all of it down. As vapors were sucked into its engine, an idling pickup at the bottom of the tower began to rev up, according to witnesses. A worker raced to turn it off, however he was too late. Somewhere in the cloud of fumes, maybe within the truck’s engine, a spark touched off the gas and ignited a firestorm.

HOW A REFINERY WORKS

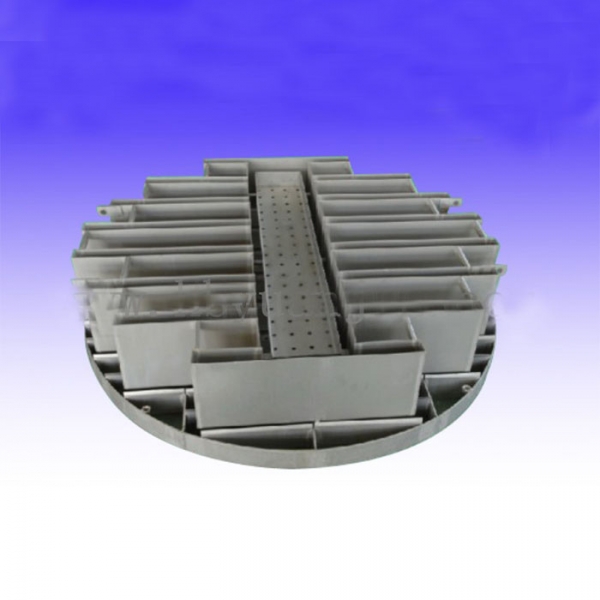

Refineries separate uncooked crude oil into its varied components, known as fractions, by profiting from the distinct boiling level of every. The process begins with fractional distillation, when crude oil is heated to about 720 F. Sizzling liquid and vapors enter a distillation column the place the vapors cool as they rise, condensing on collection trays at totally different heights. These liquids, resembling naphtha and kerosene, might then be diverted to other models for further processing. Each gas is made of a distinct chain of hydrocarbons, and manipulating these molecules produces completely different petroleum products. Cracking models and cokers break large chains into smaller ones to create medium-weight and heavy fuels. Alkylation items mix quick chains, forming mainly aviation gasoline. Isomerization units rearrange the structure of molecules to turn naphtha into high-octane gasoline.

SHOCK WAVE

Spring is often when refineries buzz with maintenance work to arrange for summer season’s heavy gas demand, and that morning workers from quite a lot of contractors had been within the vicinity of the isom unit. Throughout the road, a contractor overhauling a turbine at a cogeneration plant heard a pair of distinct explosions–one quiet, one loud. He instinctively checked for shrapnel. “I seemed up, and the sky was clear, so then I appeared over at the guys on the scaffolding,” he says, referring to males working close to the isom unit. “They were simply gone.”

When a cloud of highly flammable materials is ignited, two events happen virtually instantaneously, producing two audible blasts. First, an preliminary flash consumes all available oxygen, creating a giant vacuum. As soon as the suction brings in fresh oxygen, the combustibles explode right into a effectively-fueled inferno that flings a shock wave in front of it.

At close vary, this supercompressed wall of air is actually visible as it rockets outward at more than 1000 ft. per second. Ramirez says he noticed it just earlier than it blew him to the ground. But his colleagues would have had no warning earlier than it slammed into the flimsy frames of their trailer places of work. Eleven of Ramirez’s teammates had been killed instantly by the blunt drive of the shock wave. A fireball then rolled over the shattered trailers and melted nearby porta-potties.

Investigators now suspect there may have been as many as 5 separate explosions, in fast succession–including one straight beneath the trailer Ramirez had just left.

Nearly a mile from the explosion, BP retiree Shera Shurley was watching Tv in her cellular house when its windows blew in. She ran outside to escape. Standing in her driveway, she appeared on the swirling black cloud climbing into the sky. There was no sound, she remembered later, not even a siren.

Texas Metropolis’s emergency providers crews began rolling moments after the isom unit shattered. BP maintains its personal fire brigade, and has a mutual response plan with the brigades of the opposite two Texas Metropolis oil refineries, owned by Marathon Ashland Petroleum and Valero. They get loads of practice: Based on Texas Metropolis Fire Division chief Gerald Grimm, BP had 30 fire alarms in 2003 and 27 in 2004, though he says this was no more than different plants of a similar dimension.

Soon seventy five native, regional and industrial emergency response models surrounded the location, the place walls of water erupted from “monitors”–strategically located water cannons, each capable of hurling up to 1500 gal. per minute. The thwack of rotors could possibly be heard pounding via the thick smoke overhead. First on scene were news choppers, adopted by a Life Flight helicopter from Memorial Hermann Hospital in Houston. Just 20 minutes after the accident, the airspace had turn out to be so crowded that the Federal Aviation Administration declared a no-fly zone 3000 ft. excessive and three miles vast.

At the end of 1 hour, the fireplace had been contained, and within 2 it was almost out. Only then did the tally sink in: 15 lifeless, over one hundred injured. Of the fatalities, greater than two-thirds labored for Ramirez’s workforce, and had nothing to do with the unit that exploded.

HOW THE ACCIDENT Occurred

Based on the Chemical Safety Board, computerized data from the management system equipment point out pressure contained in the manufacturing tower (1) rose quickly from 20 psi to 60 psi. This triggered three pressure-relief valves (2) to open for six minutes, discharging enough gas into the blowdown drum (three) to overwhelm the system. Petroleum couldn’t be recycled back via the refinery (4) quickly enough, forcing liquid and vapors up the one hundred twenty-ft. stack (5). As gas settled to the ground, it ignited in a blast strong sufficient to rip the roof off a benzene storage tank 300 yards away. Investigators found that a 6-in. drain leading to the plant sewer (6) had been chained open. Fumes touring under the refinery may have fueled one of what is believed to have been 5 explosions.

BLOWDOWN

Texas Metropolis is aware of industrial amenities and their dangers. Often referred to as “Toxic Metropolis,” it’s home to four chemical plants and three refineries. The sprawling BP advanced, built in 1934, is the third largest of 149 petroleum refineries nationwide. At night time it glows like a forested panorama of steel Christmas timber, strung with flickering security lights. Since data had been stored in 1971, there have been not less than nine different accidents at the refinery that injured or killed staff, but the explosion on March 23 was by far essentially the most destructive.

In the weeks following the accident, BP’s operations got here underneath intense scrutiny. Blowdown drums are a typical feature at refineries, as are towers used to launch evaporating gases. Most tower vents, however, embrace a flare system–a kind of pilot light that ignites doubtlessly hazardous vapors as they funnel out. In 1992, the Occupational Security and Well being Administration (OSHA) mandated that the Texas refinery change to a flare system. Amoco, which merged with BP in 1998, appealed and OSHA withdrew the request. The refinery continued to use stacks that allowed gases to flee.

Former BP worker Wydell Dixon says she has seen lightning ignite vapors wafting out of the isom stack. Whether a flare would have finally prevented the explosion is questionable given the quantity of liquid as well as vapor concerned, says Don Holmstrom, an investigator with the U.S. Chemical Safety and Hazard Investigation Board (CSB), however “a flare does present an additional layer of security.”

The situation of the short-term trailers also has been questioned. BP guidelines allowed trailers within 350 ft. of refining items–no less than two have been inside 150 ft.–provided they receive site-particular evaluation. (BP has since mandated trailers be positioned no less than 500 ft. away.) Some other refiners take the additional precaution of requiring nonessential personnel to be evacuated when items just like the isom are being brought on line. In response to BP spokesman Hugh Depland, BP has no such requirement.

OSHA and CSB are both conducting investigations. In keeping with Holmstrom, the CSB is wanting into such factors as whether or not the gas was heated too quickly, which may have led to the stress spike in the tower, and whether or not all outflow valves had been working correctly. An official report is not anticipated for up to a year. BP can also be conducting an investigation. Says Depland, “It can be inappropriate to touch upon an investigation that is ongoing.”

Ramirez, who survived the explosion, was left wondering if an evacuation order that might need saved his colleagues was ever passed along. His boss, Eugene White, may need recognized, however he died when his trailer workplace was demolished by the shock wave.

A week after the accident, workers carrying a who’s who of petro trade caps gathered between shifts within the Texas Tavern. One stated a buddy had give up; he’d been having lunch with his wife in a minivan when the plant blew proper in entrance of them. Another person noted the date: exactly a yr since an explosion in another unit at the plant. Quickly the bar grew crowded with men drinking longneck Buds and capturing pool. Down the road on the refinery, skeletal cranes, shrouded in fog, continued to select over the rubble.

Tom Price is a contract author.

T.J. Aulds is an editor for the Galveston County Every day News.

In the event you cherished this article and you want to acquire more information regarding by product in petroleum refining i implore you to go to the web page.